Purchasing Adjustments

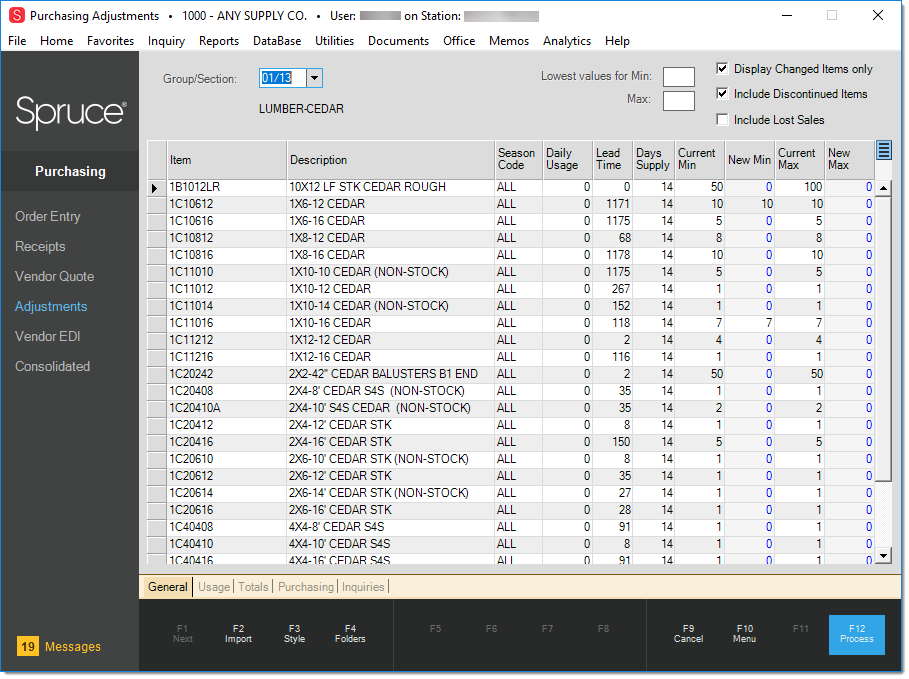

This activity is used to change or view minimum, maximum, and other purchase related Item settings for items. The item database contains settings such as minimum, maximum, and lead time quantities that are used for purchasing (under the Branch and Codes folder tabs). These settings can be set manually as static numbers, or they can be set up to calculate based on different criteria.

When minimum, maximum, or lead time are set up to calculate based on changes to other data, the Adjustments activity is used to initiate an update of the figures; otherwise, an item's purchase settings (for calculating minimum, maximum, or lead time) are not updated independently.

Maximum quantity is intended to be used as the quantity that should be maintained in stock (shelf quantity, for example). Minimum quantity is intended to be used as the re-order point for the item in question. Maximum may be calculated based upon average usage or a quantity that's manually set by the user. Minimum quantities may be calculated as a percentage of the maximum or manually set by the user.

Items may be typed into the grid, imported using inventory selection (keyword, location, etc.), an existing document (Wizard), a Windows-based File (Wizard), or selected by group/section in the main form. A combination of some methods may also be used. By default, the grid only shows items that will be changed based upon their Item settings. To view all items within the selection, clear the check box next to "Display Changed Items only."

TIP: The application uses the usage interval to determine the number of days to calculate the Average Daily Usage (for example: April 1 – June 30). Purchasing Adjustments take the Average Daily Usage and multiply it by the Lead Time Days + 1 to come up with the Suggested Minimum quantity. The application calculates the Maximum quantity by taking the Average Daily Usage quantity and multiplying it by the Days Supply. Therefore, if you set a Days Supply and Lead Time you will get the best results. If you use 30 days as the Days Supply and 14 Days as the Lead Time, you have a two-week minimum and four-week maximum.

A check box that determines whether discontinued items are included is provided. Discontinued items are not included on automated Purchase Order builds so purchasing settings used by builds such as minimum, maximum, days supply, etc. would not typically apply to them (unless their status changes in the future). Including discontinued items won't cause problems, however, the settings just won't be considered for those items when processing a build. Clear the "Include Discontinued Items" check box prior to populating the grid if you don't want to include discontinued items.

A user can add lost sale quantities to the usage minimum/maximum calculations by selecting the "Include Lost Sales" option. If you do not want to include lost sales, uncheck the option prior to populating the grid.

Lowest Values Settings

Prior to populating the grid with items, it's possible to set a "lowest value" default for minimum and maximum quantities. If an item's minimum quantity is below the lowest value (min) then the item's minimum will be set to match the minimum designated. This works the same way with the maximum, if an items maximum quantity is lower than the lowest value (max) specified, the maximum for the item will be adjusted to match.

Example: Updating a Group/Section

Here is specific examples of how this activity might be used:

-

From the Group/Section selection box, choose the group and/or section from the tree.

-

Selected items copy into the grid if any items would generate an automatic adjustment.

Application calculated figures display in blue text. -

Manually adjust any line items as needed. Manual changes appear in green text.

-

Once all changes are complete, use the Process (F12) function to update the Item database.

How are Automated Calculations Done?

Items can be set up to either calculate purchasing quantities automatically* or use quantities that must be adjusted manually. Calculations that determine maximum quantity use average daily usage for projecting the needed quantities over a period of time (determined by either the item's days supply or usage interval). Average daily usage is calculated using prior year's usage if it exists. The beginning of the usage period considered is based on the current date less one year. The end is determined by the days supply or usage interval assigned to each item. Usage is only maintained by month, so the smallest average usage figure is equal to the average for the starting month. Usage periods that pass the end of the starting month would prorate the average usage based upon the number of days being considered in each monthly period (not an average of the average).

*Automatic methods still require processing in Adjustments to keep figures up-to-date based on item activity.

The starting month in the prior year is determined by the current date. Either the item's "day's supply" or "usage interval" is used to determine the number of subsequent months (in the prior year) to include in the average usage calculation. If the "usage interval" is set, it will be used instead of "days supply." Each month involved in the calculation calculates its own monthly average based on the number of days in that month, these are then used to calculate an average for the entire time period.

For items established date in the current year (no prior year usage), the starting date for the usage period is set to the current date less the item's days supply. This period is then used for determining average daily usage. If items have no established date (due to a conversion, etc.), the most recent stock value record will be used instead.

Average daily usage is projected for the number of days supply (or usage interval) and used to determine the new maximum. Minimum quantities can be set as a percentage of the maximum figure.

Additionally, it's important to know your inventory:

-

Keep in mind any promotions (sales, etc.) that might have inflated the quantity sold for a period of time.

-

Make sure that items which are "seasonal" are set up appropriately so that they are not ordered (or stocked) when they won't be sold. Seasonal codes should be used to indicate when items are ordered which is not necessarily the same as the time period when they are sold (for example, a company located in the Northeastern United States is probably not going to replenish their supply of lawn mowers in August even though they are likely still being sold during that time).

-

Remember, minimum and maximum settings can be determined on an item-by-item basis. All items don't have to use the same method. Some items will work better with more manual control and others with calculated quantities.

Importing Items

One variation on this process would be using the Import (F2) Inventory or Wizard function to select items. The Inventory import allows selection based on groups and sections (which is really the same as using the Group/Section drop down on the form), keywords, classification, or location code (or a combination of these). The Wizard can be used to import options from an existing document or Windows-based file (spreadsheet, delimited file, etc.). Caution! The Import (F2) function replaces all previous entries in the grid each time it is used

Processing Adjustments

Carefully review any changes. Once all entry is complete, choose the Process (F12) function to update the item database with the changes. There is no process form or document associated with adjustments; however, users can print the grid prior to processing if a paper record is desired.