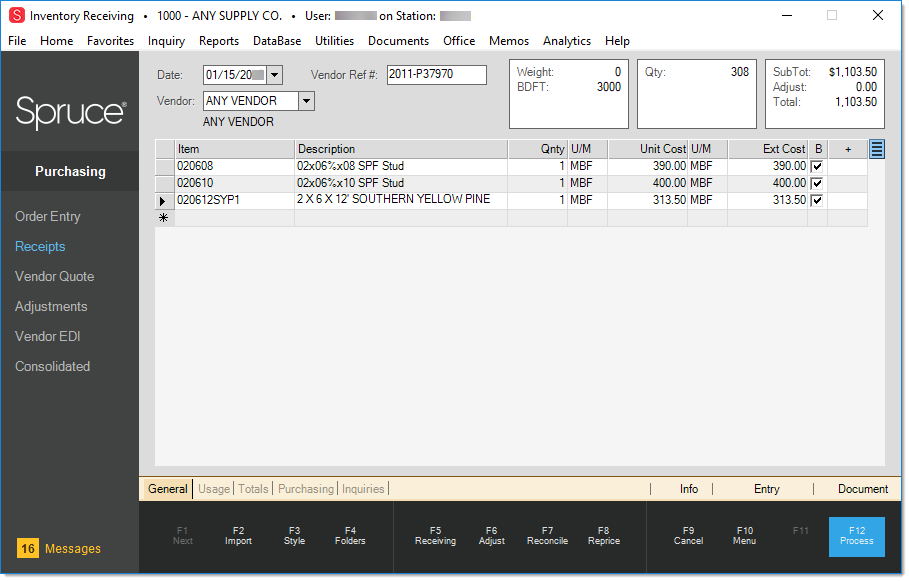

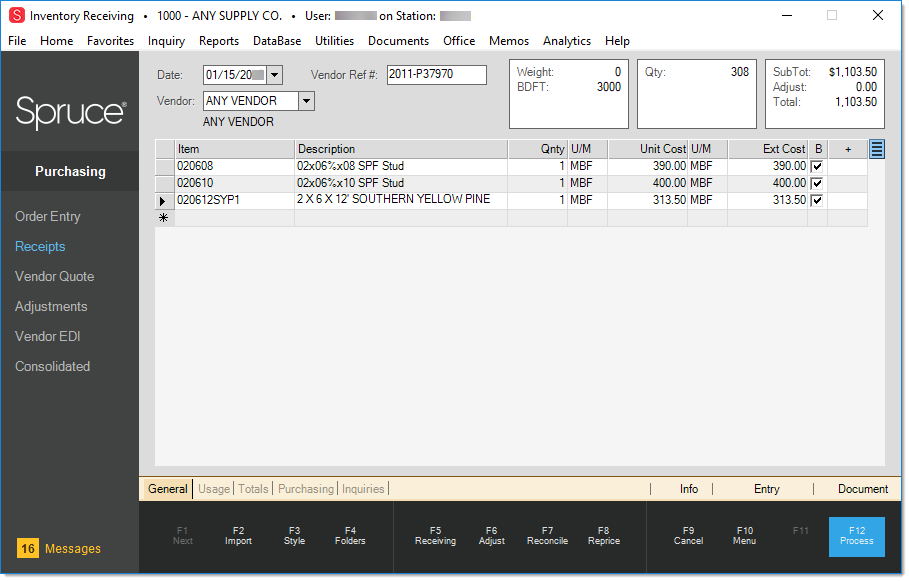

This activity receives goods into your company's inventory increasing on-hand quantities and updating costs. For items that were "ordered" on a purchase order, the on-order quantities are reduced when they are received. A receipt may involve a purchase order or may simply be created from items entered or scanned manually. Item entry can be done at any time, but vendor selection is required for processing.

Date selection defaults to the current day unless changed. Ideally, receiving should be done on the date the goods are actually delivered in order to keep the on-hand and on-order quantities as accurate as possible. Future and past dates are permitted if your company allows it; however, it isn't always a good idea. On hand and other figures are still updated immediately and the actual process date is still recorded as the document's "receipt date." The date entered by the user is considered the "post date." Reports, selection listings, etc. may or may not include post dated documents. Task list warnings are available that can be optionally elevated to an "error" severity level to prevent either future or past dates.

The entry of a vendor's reference # (packing slip, etc.) may be set to be either optional or required. The system administrator decides whether leaving this field empty generates an error (requiring entry before processing) or just a warning which may be ignored (the default is a warning). A receiving document will be created regardless of whether or not a vendor reference number is entered. Entry of some type of reference/description is required during A/P (accounts payable) processing.

The vendor selection is used to indicate the supplier of the materials being received. This "materials" vendor can be linked with another "pay-to" vendor to whom payment is remitted (such as a co-op, etc.) --or-- the material and pay-to can be the same. Vendors can also be linked to a particular EDI (Electronic Data Interchange) interface. Only vendors who are linked to an existing EDI interface can use Vendor EDI options for electronic updates and submission of data. Only specific vendors support EDI processing and other requirements may apply.

Receiving Inventory Procedures

There isn't necessarily one "right" way to receive inventory using the application. Each company must choose the best method from the options provided. Below are a few different methods that can be used:

In this case, we are immediately copying in all of the items ordered on a purchase order and updating those items in the data grid. This generally works fine for smaller orders or if you are choosing to "blind receive" a purchase order that was previously updated by EDI processing; however, it is cumbersome for larger orders since you have to locate the items in the data grid if changes are necessary.

Use the Receiving (F5) function to select either an existing purchase order or mobile receipt to associate with the transaction.

Once the items from the selected order have been added to the Receipts transaction's data grid, update quantities to match what was received as needed.

|

Please note! Scanning items won't update the existing item quantities in the data grid. Please look up: "Reconciling to a Purchase Order" for a "scan and receive" method in the Search field of the Help System.

|

If the purchase order was updated by EDI processing, the quantities listed in the data grid will be the EDI quantities, not the original order quantities. Costs on the purchase order are updated when the "Purchase Order Update" is processed in the Vendor EDI transaction to match the EDI costs. You can use the Reconcile (F7) function to view the differences between the ordered quantities and current receipt before processing.

This method involves a detailed "check-in" of the received items followed by a comparison of those results to the original order and/or EDI quantities. To begin, you specify the date, vendor, and reference then scan the items you were shipped. The process of scanning can be done either from the Receipts transaction or it can be done using the Spruce AnyWare app's Inventory Receiving option and then imported using the Receiving (F5) function.

After all of the items have been scanned and had the receipt quantities set based on what was shipped, use the Reconcile (F7) function to compare the ordered (and/or EDI ) quantities to the current receipt before processing. Investigate and correct any issues found.

This option only applies to receiving when there is no EDI data involved. In this case, you simply scan or enter the items and quantities being received and then process the receipt. The downside to this option is that you don't necessarily know if what you ordered matches with what was shipped.

|

"Blind Receive" is a method usually used along with EDI (Electronic Data Interchange) processing. The name, "blind receive," is used because the process of carefully checking in each item shipped is either avoided entirely or minimally done. If the EDI quantities supplied by your vendor tend to be pretty accurate, it may make sense to consider this method. Instead of checking in each item individually, you would instead receive the purchase order based on the EDI quantities or do a quick reconcile (F7) and check for gross discrepancies only. This method makes sense if the time, labor, and resources required for checking each received item outweigh the average cost of discrepancies that may be present.

Before instituting a "blind receive" method, you should be confident with your EDI process and that your item data and settings for purchasing are correct most of the time. It's best to monitor the amount of discrepancies found during receiving for a period of time before making a decision. If your company is spending significant time receiving orders and that process isn't identifying any or many discrepancies over the review period, consider this option.

|

Item Entry in the Data Grid

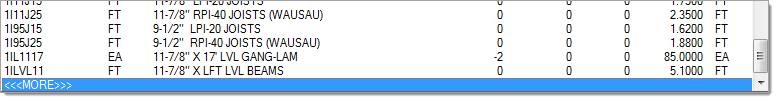

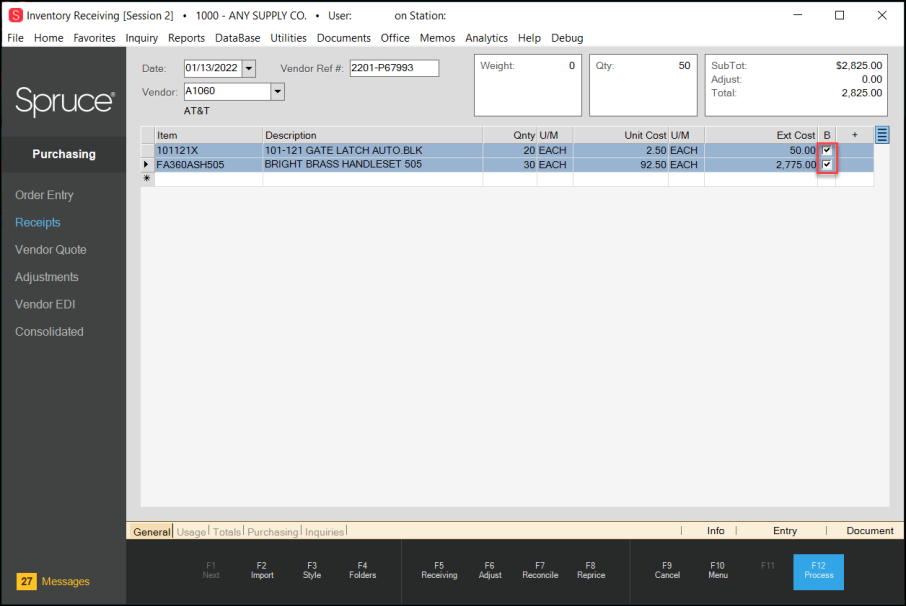

The grid is similar to those found in other areas. The Receipts data grid includes the item code, description, quantity being received, quantity measure, unit cost, cost measure, extended cost, and two (2) additional columns used to indicate the backorder status and item-based attachments.

Any items that are entered with a zero quantity or cost may prompt a task list warning or error (unless "hidden"). Zero quantity items won't change on-hand or adjust the last receipt or average cost for items. Zero cost items with a quantity would adjust average cost (when applicable for the item). The receipt document won't display zero quantity items.

The column labeled "B" is used to indicate the back order status of items in the grid. The default flag is based on the vendor's settings. When back order is enabled (true) for the vendor, the status of the check box will be checked; otherwise, it won't be checked. Even if the vendor's back order default is N (no), you can still set the back order flag. Doing so will keep the items open on the purchase order until they are fully received. If no purchase order is being referenced, the back order status has no effect. For more about the back order process, see Back Ordering Items Not Received, below.

The "+" column is used to indicate record (item) based attachments and is common to the majority of grids. To view an item's attachments, select the item's grid row and then choose Folders (F4) and select the Entry folder tab. This tab will list any item-based attachments.

Items can be manually entered, added from an external (Windows) file or internal document using the Import (F2) function, received from a purchase order or mobile purchase order document, or scanned using a barcode scanner. If scanning a barcode and an item matching the barcode is not found, a prompt allows the user to specify an item to link the barcode. Barcode scanning is often used with the Reconcile (F7) function.

For more information about item entry and selection, click here.

For more information about item entry and selection, click here.

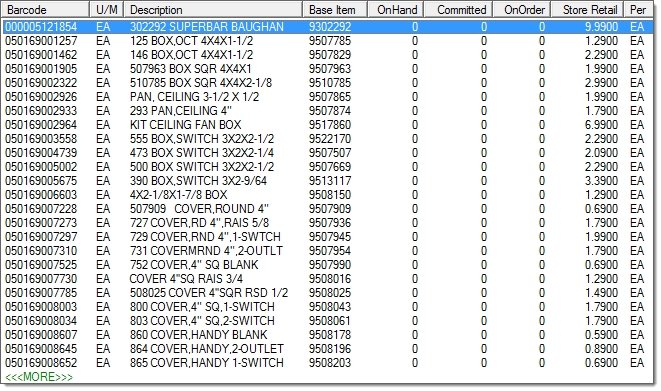

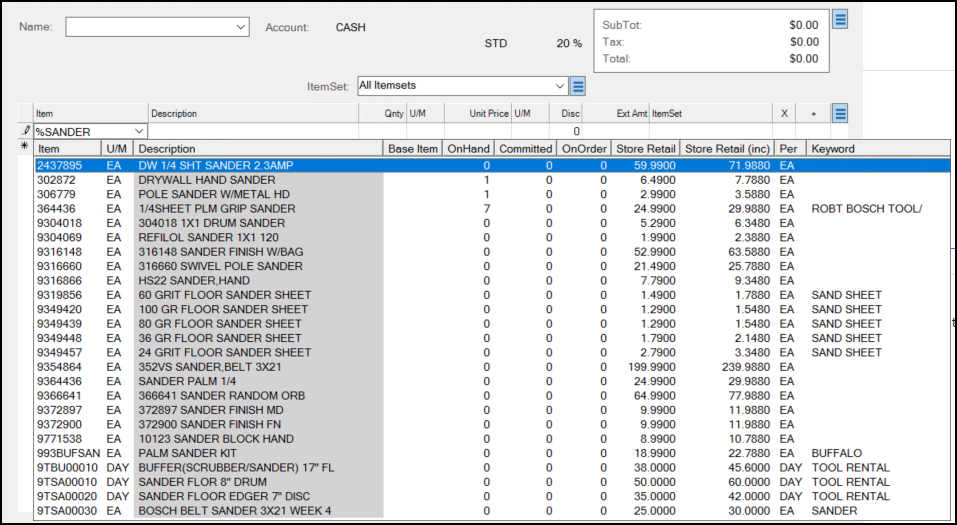

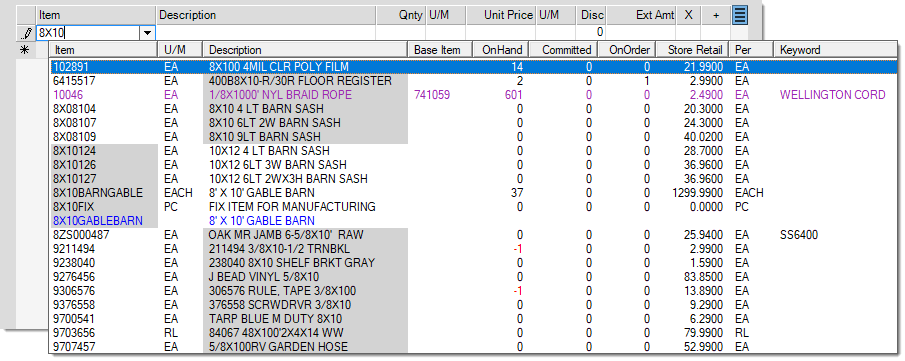

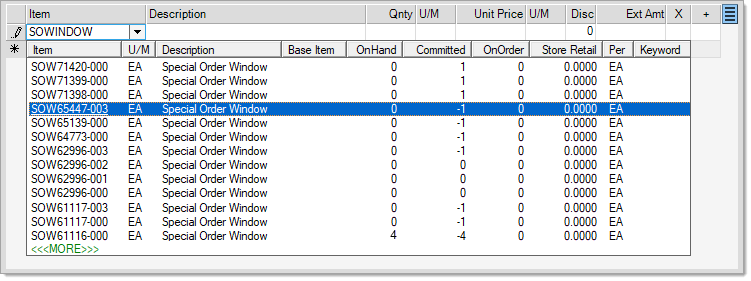

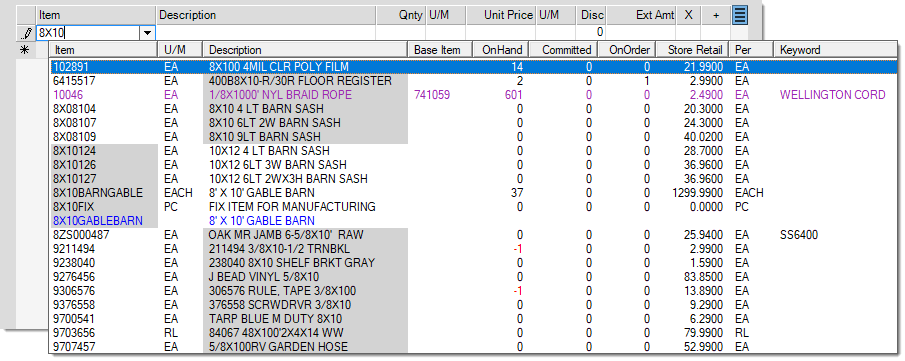

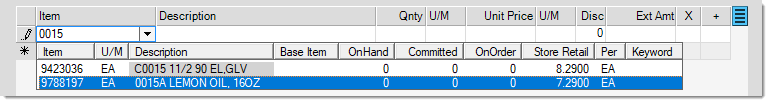

One of the most important features of a retail software solution is Item Entry. When the item is physically present, scanning the item's barcode is the easiest and fastest way to enter it into the application. If you don't have a scanner or the item has no barcode, you can always enter a full or partial item number if it's available. When entering text that partially matches existing item codes, the application displays a list of items that match. Items in selection lists are color coded to help distinguish between item numbers and alternate SKUs (in purple). On-hand quantities in a selection list are also color coded when an item has a negative on-hand (red).

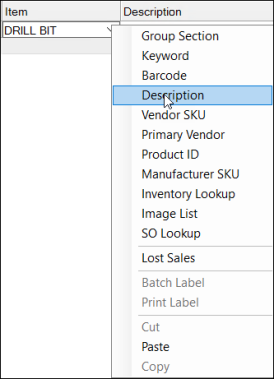

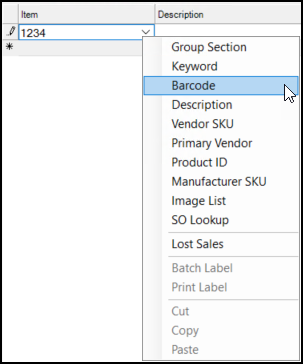

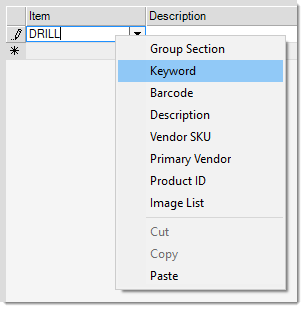

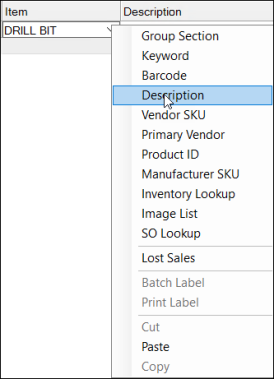

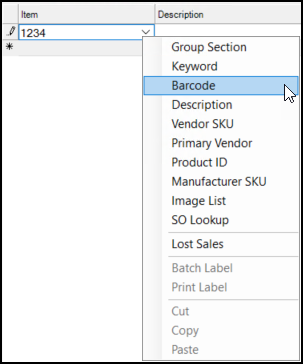

There are cases when you may not be working with any physical item, such as when you are building an order or quote, so scanning or manual item entry isn't always a realistic option. For these situations, you can enter the information you want to search for and right-click the Item list icon to display a list of search options.

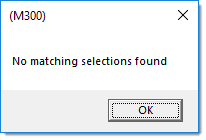

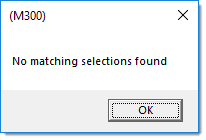

All of the following alternate selection choices are used to build a selection list matching the criteria you either enter or select. Based upon your selections, you can wind up with a list that contains a few items, many items, or one item. In addition, it's possible for your selection to produce no matches.

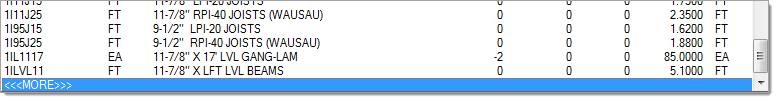

Selection listings are assigned a set "page" size. Usually, this initial listing or page is limited to the first 25 records. When more items match the criteria than the page size, a "<<<MORE>>>" option is displayed at the bottom. Clicking "more" populates the selection listing with the next page of items. Previous records (items in this case) remain in the listing and can be viewed by moving the scroll bar on the right-hand side of the listing.

|

If you want to add more than one item in the list to the data grid, you can hold down the CTRL (Control) or SHIFT key and click the items you want to add as follows:

After you select the items you want, press the Enter key. Then, use the Next (F1) key to add the items you selected to the data grid one-at-a-time.

Selected items are not automatically copied into a grid. This feature works this way because not all selections made using these keys end up in a data grid.

|

Selecting Items using Group Section

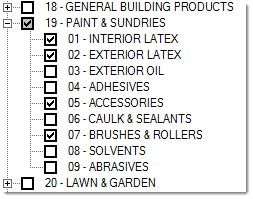

Since all items must be assigned to a group and section, you can use the Group Section settings to find an item. Groups and sections are numbered (1-255), but are also assigned a text description. In almost all cases, the text description is shown along with the numbers. Numbers are used because they take up less space and also makes sorting and searching data more efficient in the database. Each company can choose how it wants to organize its inventory.

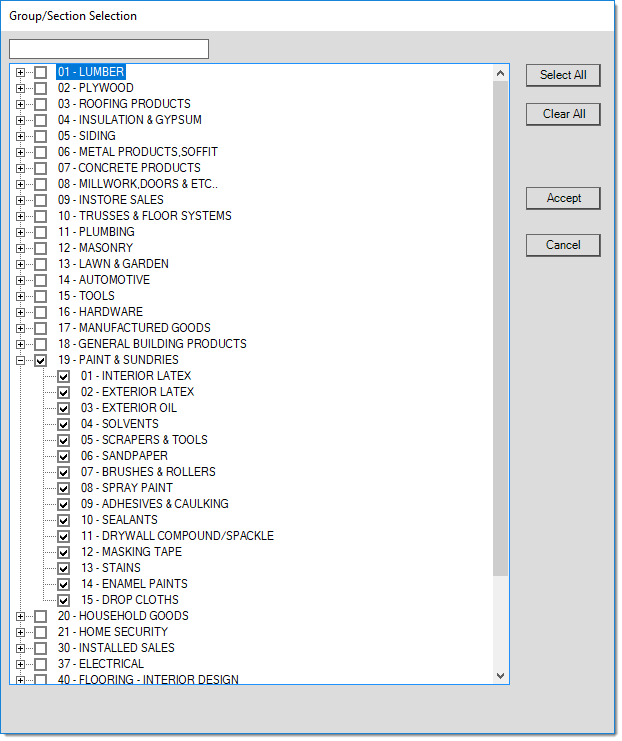

Group/Section Selection List

Group and section selection uses an expandable navigation "tree." Each group listed in the tree can be expanded to display the sections within the group. You can make multiple selections. For example, you can create a selection list of all the items in three different groups -- or -- just a few sections within one or more groups.

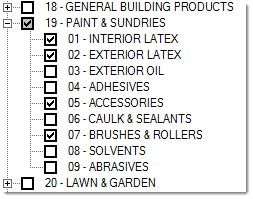

When all the items in either a group or section are selected, the check box background is displayed in white  . If you select some but not all sections within the same group, the group's check box background is changed to gray

. If you select some but not all sections within the same group, the group's check box background is changed to gray  . Use the Select All button to select all groups and sections. Use the Clear All button to clear all check boxes. Choose Accept to build a selection list based upon the groups and/or sections you have chosen (checked). Or, click Cancel to close the window and not build a selection list.

. Use the Select All button to select all groups and sections. Use the Clear All button to clear all check boxes. Choose Accept to build a selection list based upon the groups and/or sections you have chosen (checked). Or, click Cancel to close the window and not build a selection list.

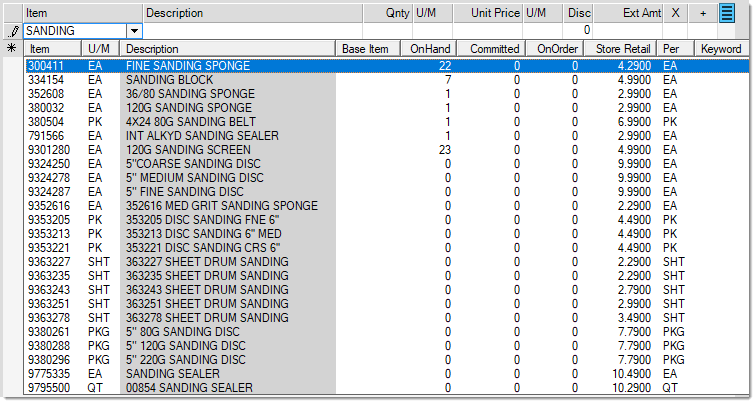

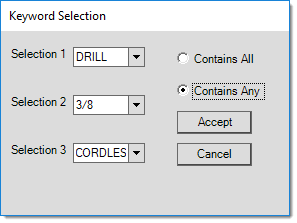

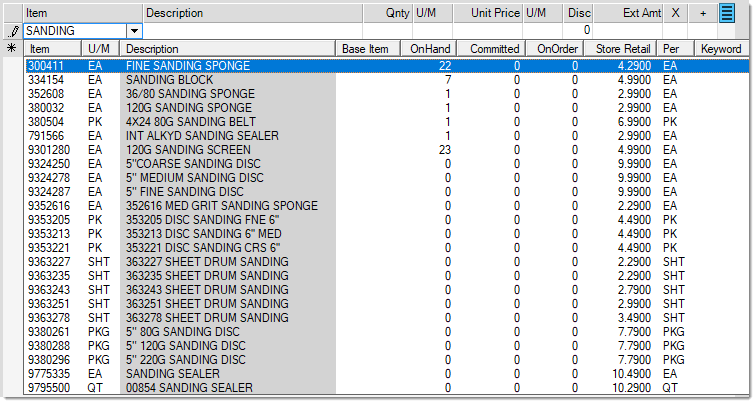

Selecting Items using a Keyword

Items may be assigned up to five keywords. Keywords are meant to be a common and intuitive word that generally describes the product. It's best to use a word rather than a phrase and to not get overly specific. Keyword matches are not case-sensitive (you can type them using upper and/or lowercase letters). Some examples of good keywords are: TRUSS, PAINT, SINK, DRILL, BRICK, etc. The more specific the keyword, the less intuitive, and less likely that it will be used. Keywords are not required on items. Try using the Description search as an alternative if you are unsuccessful.

There are two ways to use the Keyword selection to find an item you are looking for:

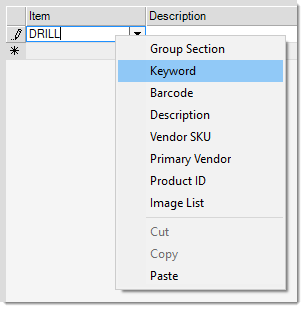

1. In the Item column, type in the word or number you want to search for and right-click the drop-down arrow. Choose the Keyword option to display a list of items that contain the word or number you entered.

2. In the Item column right-click the down arrow and choose the Keyword selection option first (before you type anything in the Item field). The application displays a Keyword Select list where you can specify up to three keywords at the same time. You can choose to match on either ALL or ANY keywords. If you choose "Contains All", only items assigned to all the keywords will be included in the selection list. If you choose "Contains Any", items with any of the keywords specified will be included.

Selecting Items using a Barcode

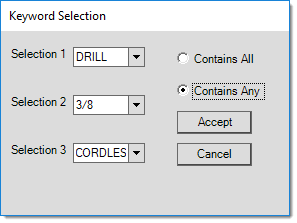

You can assign up to five different barcodes to each item. You can use these different barcodes to distinguish different units of measure (BOX vs. EACH, for example), so it's important to pay attention to the unit of measure that displays when entering quantities. This selection tool can be used with either a full or partial match on an item's barcode. Partial matches are made beginning with the first non-zero number in the barcode. Leading zeros are not considered.

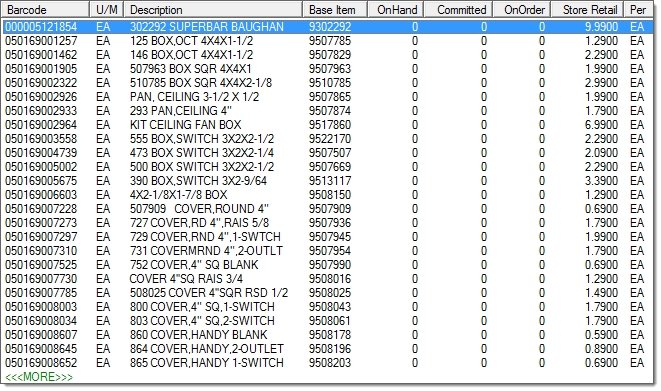

When using the barcode selection option, products are listed in order of barcode. The "base item" column contains your company's SKU for the item.

Selecting the Item using the Description

Use the Description search to find items using the words or numbers in the item's description. Matches are not case-sensitive (so it doesn't matter whether you use upper or lower case letters). The text can be located anywhere in the item's description (beginning, end, or middle); however, the entire text is matched together as a phrase, not as independent words. For example, if you type in "FAN KIT" but the item's description is "KIT CEILING FAN BOX," the application would not find the match, despite the fact that both words do exist in the item's description.

You may notice that some items populated in the selection listing don't appear to include the word you typed in the "description" column. Why is this? Items may have very long descriptions (up to 1088-characters, including spaces); however, we use a shorter truncated description for selection lists that is only 32-characters. This is done to keep selection listings a reasonable size and for database performance. The description used for locating matches is a special "search" description that is essentially the item's full description with any sequential spaces between words removed (this description also doesn't include line feed, carriage return, and other non-printing characters that might prohibit matches).

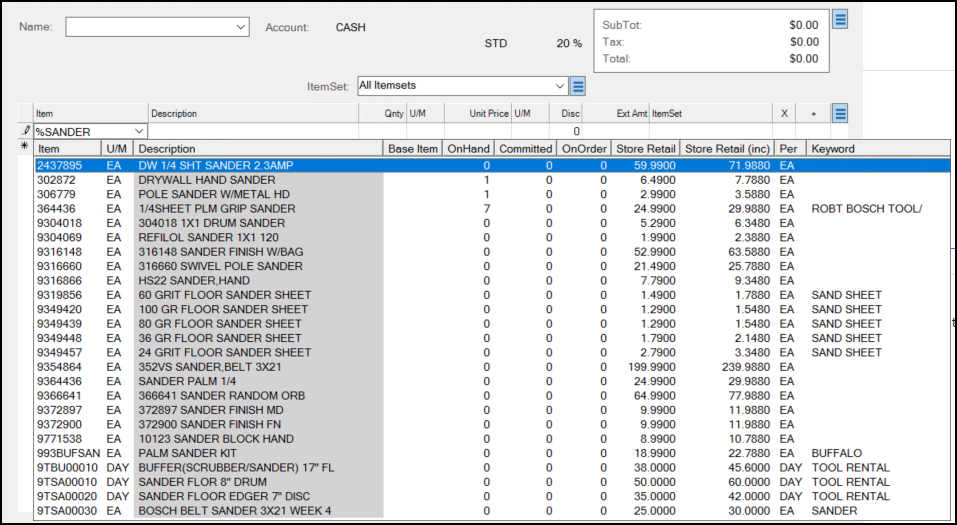

Pro Tip: If you type the character % and then the text your are searching for in any text field in a data grid, the application will restrict the search results to the records that contain that text.

Selecting Items using a Vendor SKU

Use the SKU (Stock Keeping Unit) to describe the numbers or identifiers assigned to products. Your company may use its own item numbers (codes), it may use the same codes as a supplier/wholesaler, or a mix of both of these. Each item can be assigned up to three different vendor items (or SKUs). These identifiers are used when ordering products from the vendors (wholesalers, manufacturers, buying group, co-op, etc.).

Enter in the vendor's item number (SKU) in the item drop down and choose Vendor SKU from the alternate menu. If a match is located, the matching item (or items) will display. This option only works if an exact match is located. Partial matches are not returned.

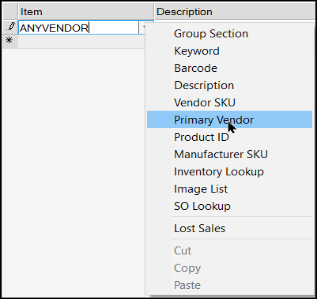

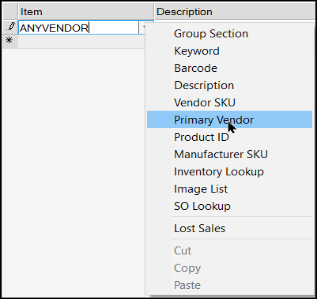

Selecting Items using the Primary Vendor

Each item may be assigned one primary vendor. The primary vendor can be different for each branch (store location). To use this selection option, enter the full vendor code associated with the vendor. This option only accepts an exact match for an existing vendor code. All items in the current branch assigned to the vendor as a primary vendor will be included in the selection listing.

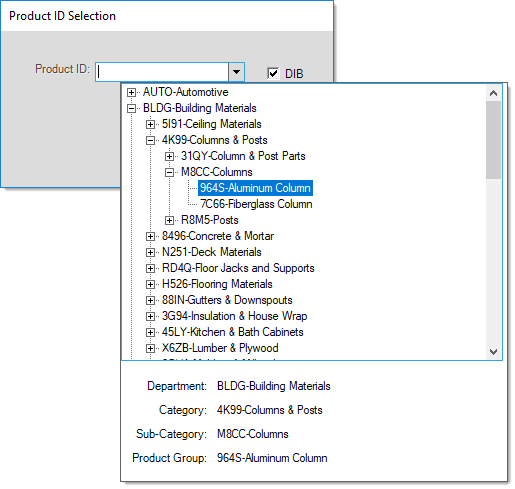

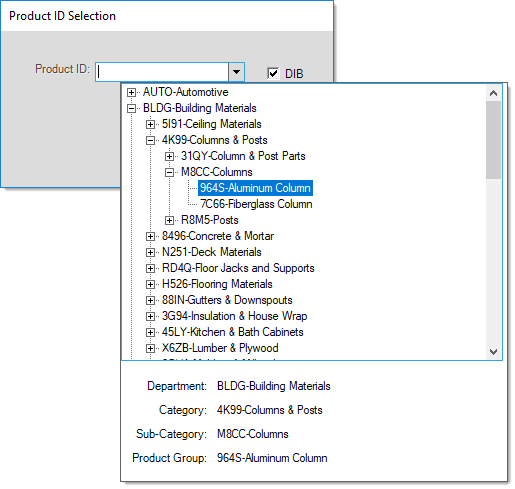

Selecting the Item using the Product ID

You can use the Product ID as a classification tool to either create custom product IDs (groups) for your related items or, if you are a Do it Best® member, you can use them to mirror the Do it Best product departments, categories, sub-categories, and product groups. You can use a combination of both custom and Do it Best product IDs; however, only one ID may be assigned per product. The same product ID may be associated with as many items as you like.

If you want to define your own product IDs, this is done from the Code Definitions form (Inventory > Database > Code Definitions) (select the "Product ID" tab from this form). To use Do it Best product categories, you must first retrieve the classifications using EDI (from the Purchasing area, choose the Vendor EDI transaction, Extras (radio button), and choose "Classification Maint."). Once this information has been populated successfully using EDI. Once completed, a "DIB" check box will appear on the Product ID selection form. This check box is hidden unless the categories table is populated with data.

Do it Best Product Classifications

If checked, the form allows you to choose either a department, category, sub-category, or product group to produce an item selection listing. If you pick a department, all items assigned to the categories, sub-categories, or product groups within that department will be included in the selection listing, for example. Items may be assigned to any level; however, it's usually best if they are assigned to a product group (the lowest level). To choose a level in the tree, double click on the node to select it.

Selecting the Item using the Manufacturer SKU

When you search for a particular item and you know the item’s manufacturer's SKU, you can use that SKU to find the item. We call this enhanced search. The enhanced search feature must be set up before you use this feature. We have added the Manufacturer’s SKU to the default enhanced search options as well.

To search by the Manufacturer SKU, enter the SKU in the Item field, select the down arrow beside the item field, and choose the Manufacturer SKU option. The application displays the list of items that match the SKU you entered.

Sale Entry Form with Manufacturer SKU Search Results

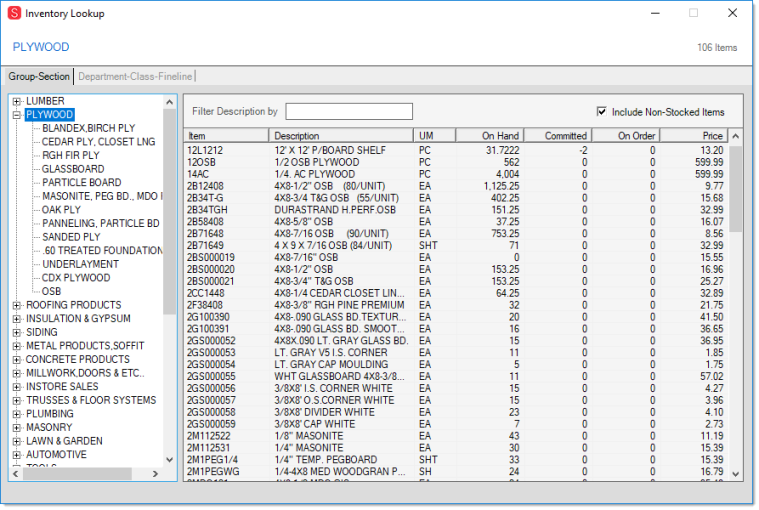

Selecting the Item using Inventory Look up

Selecting Inventory Look up will open a Utility that searches for items by Group-Section or Department - Class - Fineline.

Note: This listing includes Disabled Items.

Inventory Lookup : Group-Section

In order to search by Group-Section, all items must be assigned to a group and section. Your company may define between 1 and 255 groups and also between 1 and 255 sections within each group. Groups and sections are numbered (again 1 - 255), but are also assigned a text description. In almost all cases, the text description is shown along with the numbers. Numbers are used because they take up less space and also makes sorting and searching data more efficient in the database. Each company can choose how it wants to organize its inventory.

Select a group to view all item within that group. You may then narrow down the list by selecting the section. Click on an Item to add it to the data grid. The main dialog window will become active as soon as you select an item, at which point you can adjust quantity and price as well as continue adding items. The Inventory Lookup Utility window will remain open in the background, facilitating navigation between the windows.

You may also use the "Filter Description by" field by typing in the item number or Description. The list will narrow down as you type in more characters in the field. Check the "Include Non-Stocked Items" to include all items, included items you don't currently carry.

Inventory Lookup : Department - Class - Fineline

There are three merchandising classes available: class, department, and fineline (sometimes named "subclass"). These can be used as a selection tool. Merchandising codes are typically reserved for codes provided by vendors and may be updated by EDI processing or when adding items using a vendor's catalog.

Select a Department to view all item within that department. You may then narrow down the list by selecting the Class and then the Fineline. Click on an Item to add it to the data grid. The main dialog window will become active as soon as you select an item, at which point you can adjust quantity and price as well as continue adding items. The Inventory Lookup Utility window will remain open in the background, facilitating navigation between the windows.

You may also use the Filter Description by field by typing in the item number or the description. The list will narrow down as you type in more characters in the field. Check the Include Non-Stocked Items box to include all items, included items you don't currently carry.

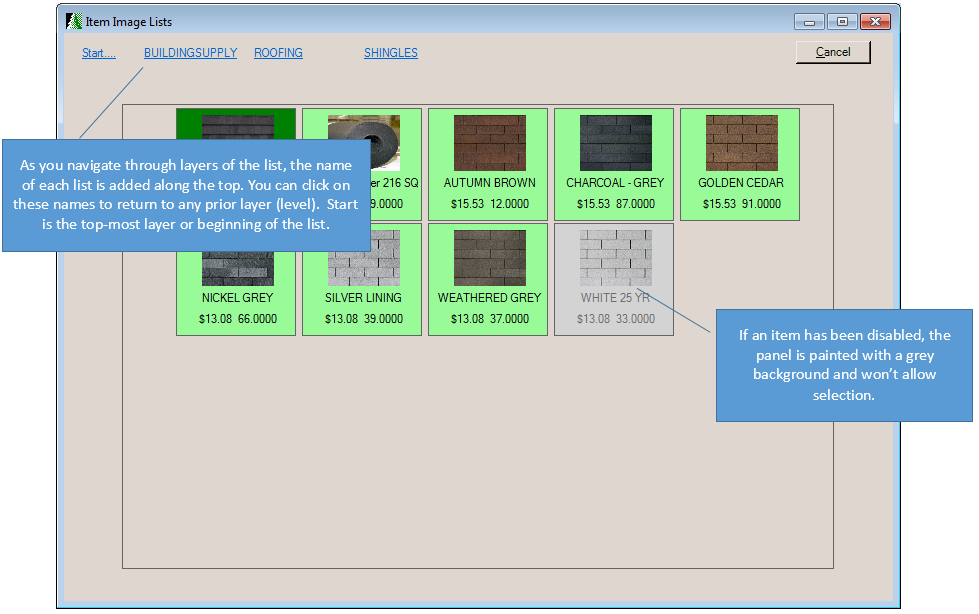

Selecting Items using the Image List Selection

The Image List feature provides a visual method for item selection. Before using the Image List feature, your company must define an Image List from the Image List Maintenance form available from the database menu in the Inventory area. There is one consolidated image list for your company. This list can have many different categories and sub-lists, however. Up to five layers of organization are permitted from the "start" location. The list should be organized from less to more specific categories and ending with items as the last level. Once a user opens the list, the list remains open in the background and retains the user's last location in the list if they re-open the list again. This is done until the user logs off, closes the application, or changes branch locations.

There are two types of content in the Image List: lists and items. Lists are indicated by either a yellow or an antique-white (light-yellow) background color. Items are indicated by a light or dark green color. The darker colors indicate the current selection. Keyboard navigation can be used as well as the mouse (single click) and touch screen if available.

Along the top of the form, navigation links are provided. Click on these to return to the "start" location or a prior list level.

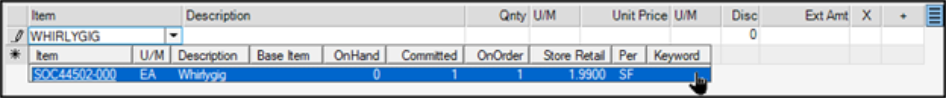

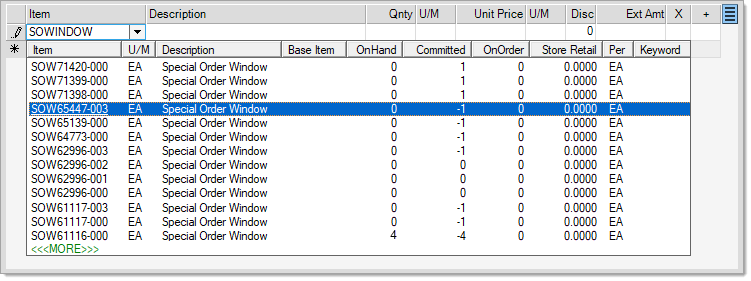

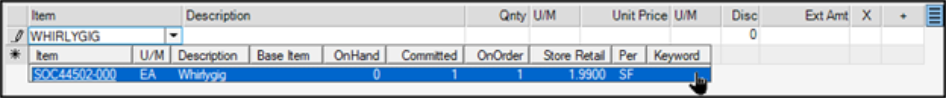

Selecting Items using SO Lookup

Search for renumbered Special Order (SO) items by entering a full or partial SO item number in the data grid, right-click and select SO Lookup. In the example below, we are searching for an item called "SOWindow". A list of all "SOWindow" items will be returned; click on the <<<MORE>>> link to view additional items of the special order renumbered SKUs. Item are listed in descending order.

Selecting Items using Lost Sales

You can track your Lost Sales using the Inventory > Utilities > Lost Sales utility form as well as from any Item selection grid or Catalog selection control anywhere in the application. Search for the Lost Sales search to find out more about this functionality.

Can't Find the Items I am Looking For, Any Other Ideas?

There are two additional search features you can use to find items quickly in Point of Sale or Inventory. Both of these features must be enabled by Implementation or Support team members. These features are discussed below.

Using the Enhanced Item Look Up Feature

When Enhanced Item look up is enabled, item selection automatically involves the following fields: item number, description, and keyword(s). The column cells matching the look up text are indicated by a gray background color. With Enhanced Item look up enabled, there is no "more" option provided and the maximum number of matches shown is 70. This means that if more than 70 matches exist, not all will be shown, and you may have to either enter additional text to narrow the selection or use other (alternate) selection options instead. Item number matches are given a preference over description and keyword matches (since alternate methods do exist for selection by description and keyword if necessary); however, the listing is finally re-ordered by Item SKU so the item matches may not necessarily appear first.

Exact matches on an item SKU do not provide a selection list.

Selection with no entry in the text area as well as selection involving the alternate menu do not use the enhanced look up feature. In these cases, item selection does provide the "more" option, and works as expected.

Typically, the more text entered, the shorter the listing of matching results will be.

The Enhanced Item Look Up feature requires setup by ECI Support personnel. Support enables a parameter and populates a special look up table using a support utility. This is only done upon request. After the Enhanced Look Up feature is enabled, ALL users and ALL locations can use it for item searches in all data grids that include items.

You can disable this feature at any time by contacting Support. If for some reason, an "enhanced" search is disabled, the tables will need to be repopulated again if it is re-enabled in the future.

Wild card searches (using the % character) are not supported when using the Enhanced Look Up features.

We have updated the ecommerce API to support the transmission of three additional fields of information:

• Discount Date

This specifies the last date that the discount applies. (This allows the API to compare the discount date to the date the payment is being made to ensure the discount can be applied.)

• Discount Amount

The calculated amount of the discount. (This provides the amount of the discount, which the API can subtract from the ROA payment balance.)

• Outstanding Amount Discount

The original amount that can be discounted, minus the discount amount, and minus the customer’s account payment, minus any additional discounts not included above.

Additional details are available in the API Guide.

Using the Enhanced Item Description Look Up Feature

When you are looking for an inventory item and cannot remember the exact name or Item ID, you can use a tool for searching the item descriptions to find the right materials quickly. The Enhanced Item Description Search features to give you those tools. Traditionally, you were restricted to searching for 32 characters when you used a Description search, we have expanded this to 300 characters, when needed. Additionally, we have added additional description search tools, such as using quotes (“Drill Bit”) and using wild cards (Drill B*) to help search for items using their extended item description. The search results show the closest matches at the top and any additional results that match the criteria below.

You can use this feature wherever there is an Item list (Point of Sale > Inquiry > Item Maintenance, etc.) and is restricted to ECI Hosted customers only. Adding this feature requires a lot of additional database overhead, which we can manage better in our hosted environment. To enable this feature, reach out to the Implementation or Support teams; as it is disabled by default. Once enabled, there are no special permissions required to use this feature; it is accessible to all users.

Search for the Enhanced Item Description topic for more information.

|

Accidents can happen. If you accidentally receive a purchase order, or some items, you can resolve the issue by using either of two (2) methods depending upon the timing of when the problem is noticed.

If the problem is noticed immediately, or on the same date as the receipt, you can reverse the receipt from the Cost Corrections transaction located in the Inventory area. To do this, choose the "Receipt Document Adjustment" option, select a vendor and receipt document, and then choose the Backout (F5) function.

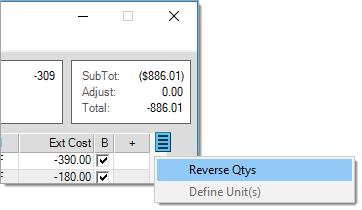

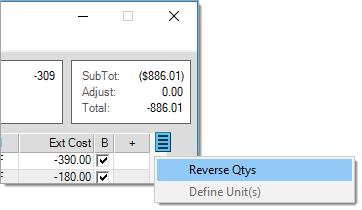

When the problem isn't noticed on the same day, the process is different. In this case, you would have to Import (F2) the original receipt from the Receipts transaction in Purchasing. Next, use the "Reverse Qtys" option (see below) to reverse the quantities from positive to negative values. Remember to duplicate any adjustments as needed prior to processing.

The Menu Marker  , located near the upper right-hand corner of the data grid, offers a "Reverse Qtys" option. If selected, this will reverse the quantities on all items in the data grid. This is useful if a purchase order is received more than once by accident, for example. You can Import (F2) the original document and then use this option to change the quantities to negative values.

, located near the upper right-hand corner of the data grid, offers a "Reverse Qtys" option. If selected, this will reverse the quantities on all items in the data grid. This is useful if a purchase order is received more than once by accident, for example. You can Import (F2) the original document and then use this option to change the quantities to negative values.

Purchase orders may contain stock allocations for specific branch locations. This may be the result of either a Consolidated purchasing activity or manual allocations done in Order Entry. In either case, there are things to consider and be aware of in these cases.

Receiving a purchase order with allocations does not automatically affect on-hand quantities in the allocated branches. Only the current branch's inventory file reflects a change in on-hand. This is because the current branch is always considered to be the "warehouse" or "master branch" from where the goods are to be distributed to the satellite locations. The movement of inventory is accomplished by using the Transfers activity's PO Build function to move stock from the receiving branch (warehouse/master) to the allocation branch specified in the original purchase order.

On-order quantities are another concern regarding purchase orders containing allocations to branches. When allocations are done and the PO is ordered, the on-order quantities are affected in each branch location based upon those allocations. On-order quantities are reduced when the PO is eventually closed. Purchase orders are automatically closed if all of the goods are received. However, in the case of a back-order, the purchase order is not closed, so the on-order quantities at the branches are not reduced. If a purchase order containing allocations is not fully received, it is a good idea to mark it closed manually and create a new purchase order for any remaining goods that are yet to be shipped. Otherwise, the branch on-order quantities won't reflect the appropriate figures.

In the case of back orders, the application has no way of determining how allocations should be handled. For example, if your PO has 100 widgets ordered overall with 50 allocated to branch ABC and 50 allocated to branch XYZ but the vendor ships 75, the software can no longer allocate 50 to each location. The determination of where the stock will go becomes a manual human process at this point. Branch allocations are not suggested for vendors who backorder for this reason.

Back Ordering Items Not Received

To ensure a successful back order, the vendor must allow back orders for their items. In the Vendor Maintenance form on the Codes tab, there is a back order option, which the application uses to determine whether the vendor allows items to be back ordered. If this option is Y (for Yes), you can process back orders for items not shipped to you during the purchasing process from your vendor.

Note: The Vendor must be active to use this process.

To back order items not received after a purchase order has been submitted:

1. In the Purchasing list, choose Receipts to display the Inventory Receiving form.

2. Click Receiving (F5) to display the PO Purchase Orders list.

3. From this list, choose the purchase order that contains the partially received items and click Accept.

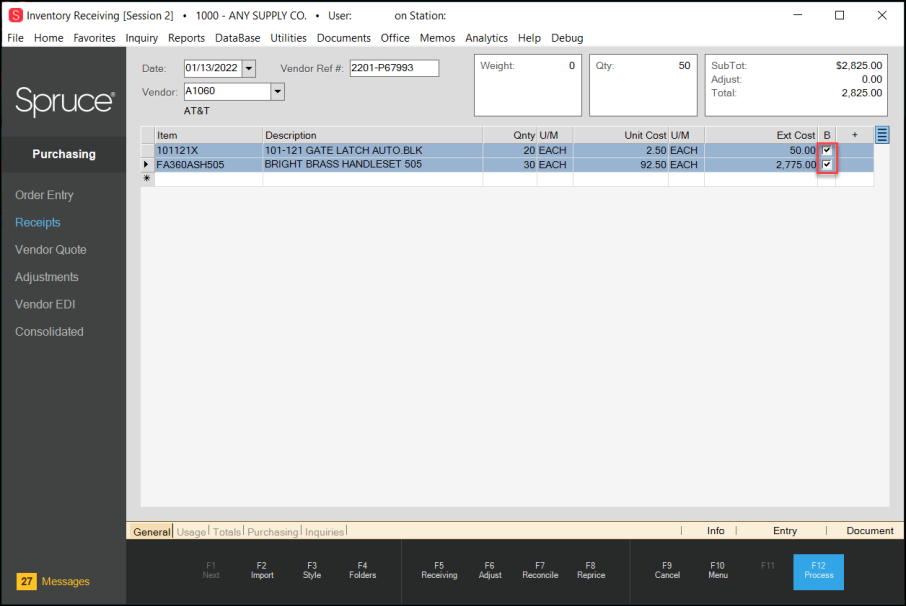

The items display in the data grid with their original quantities. The Back Order (B) check boxes display for both items by default.

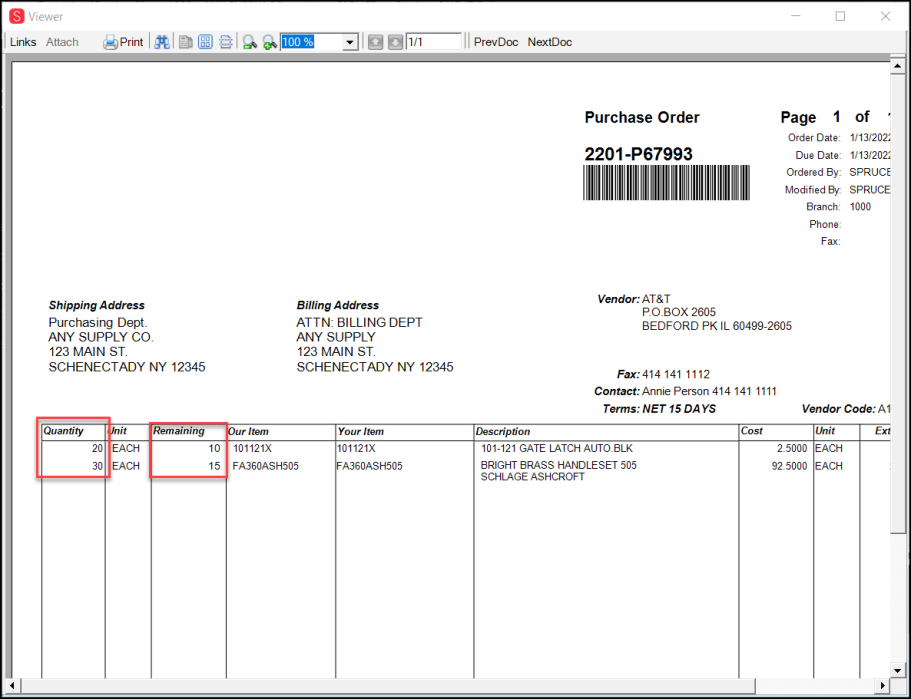

Inventory Receiving Form with Back Order Check Box Highlighted

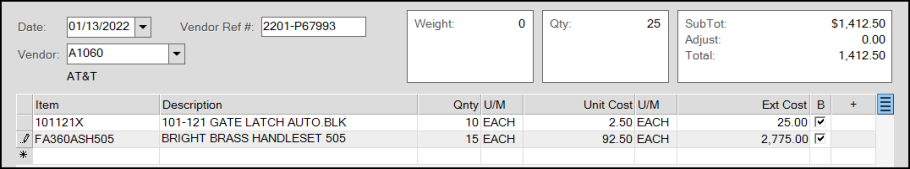

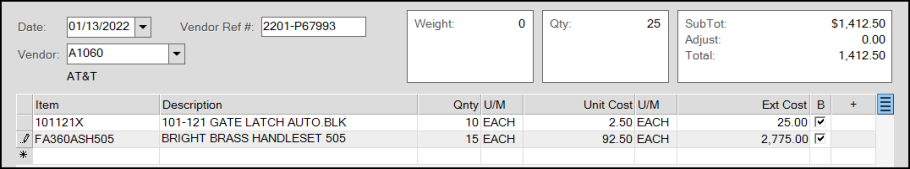

4. In the Qnty column, enter the received quantities for each item.

When the quantity ordered is more than the quantity received, the External Cost column and the Subtotals section update with the new values.

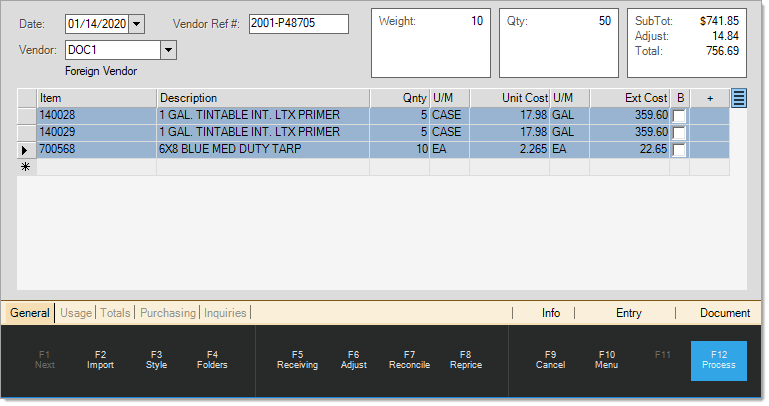

Inventory Receiving Form with Received Quantities Entered

5. Consider whether you want to back order the items that were delivered short.

-

To back order an item that was delivered short, leave the B check box selected.

-

To accept the number of items shipped without back ordering the remaining items, uncheck the B check box.

6. Click Process (F12) to record the items received and click Finish.

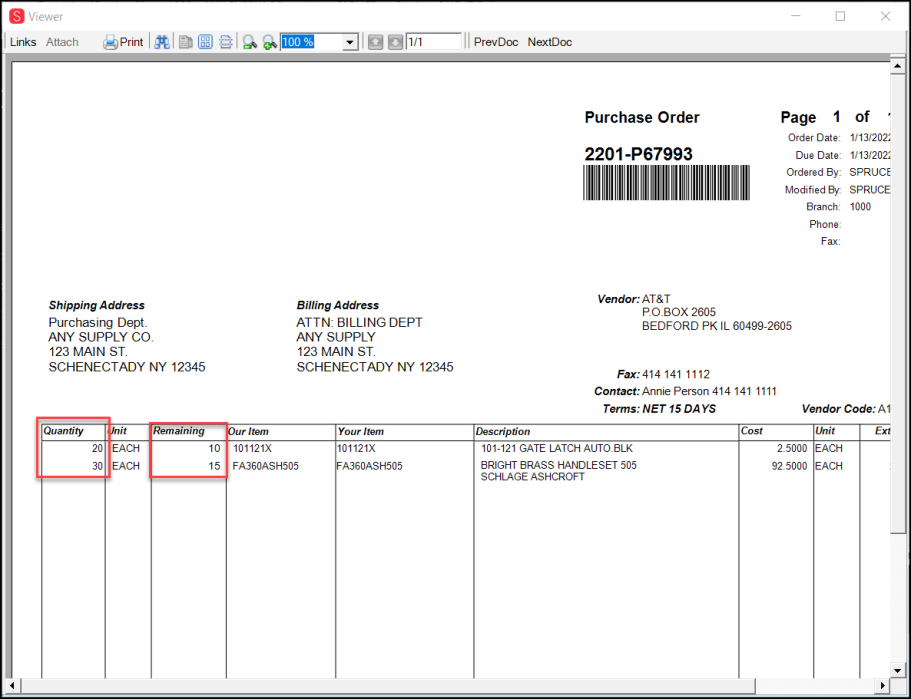

7. To see the back ordered items, go to Documents and look up the Purchase Order document number.

The Purchase Order shows the original quantity and the remaining items that are back ordered.

Purchase Order with Back Ordered Quantities in the Remaining Column

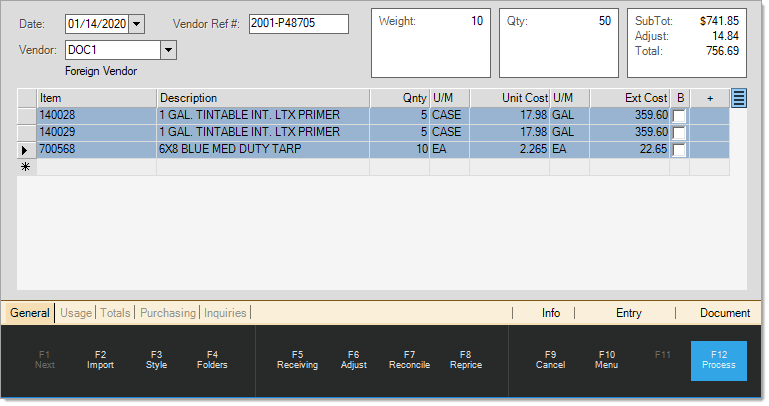

Multi-Currency

Multi-currency allows you to order merchandise from a foreign vendor. Items (and adders) are entered in the PO in the vendor's currency (see Order Entry). When the PO is received, the amounts will be displayed in your local currency. Items or adjustments added to the receipt will be displayed in the local currency. The Multi-Currency option must be turned on in Maintenance>Database>Parameters and you must have a vendor designated as a Foreign Vendor. Exchange rates are defined in Currency Code Maintenance and must be updated manually as exchange rates routinely fluctuate.

Folders

Folders in the Receipts activity are identical to those found in Order Entry. Click here to review folder contents as documented for Purchasing applications.

![]() For more information about item entry and selection, click here.

For more information about item entry and selection, click here.

![]() , located near the upper right-hand corner of the data grid, offers a "Reverse Qtys" option. If selected, this will reverse the quantities on all items in the data grid. This is useful if a purchase order is received more than once by accident, for example. You can Import (F2) the original document and then use this option to change the quantities to negative values.

, located near the upper right-hand corner of the data grid, offers a "Reverse Qtys" option. If selected, this will reverse the quantities on all items in the data grid. This is useful if a purchase order is received more than once by accident, for example. You can Import (F2) the original document and then use this option to change the quantities to negative values.

. If you select some but not all sections within the same group, the group's check box background is changed to gray

. If you select some but not all sections within the same group, the group's check box background is changed to gray  . Use the Select All button to select all groups and sections. Use the Clear All button to clear all check boxes. Choose Accept to build a selection list based upon the groups and/or sections you have chosen (checked). Or, click Cancel to close the window and

. Use the Select All button to select all groups and sections. Use the Clear All button to clear all check boxes. Choose Accept to build a selection list based upon the groups and/or sections you have chosen (checked). Or, click Cancel to close the window and