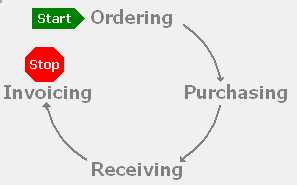

Non-Stock Ordering Process

This topic explains the standard non-stock ordering process. Users should be aware that there are some variations on this process when either Direct Ship or Manufacturing procedures involve non-stocked goods. The standard ordering cycle has 4 main components: ordering, purchasing, receiving, and invoicing.

Stage 1: A Customer Places an Order (Ordering)

The cycle begins when a customer requests goods that are not normally stocked by your company or that need to be manufactured. Given the customer's request for goods, a Point of Sale user creates a "customer order" using non-stocked items. Non-stocked items provide the ability to enter or build a description, specify pricing, and ordering information. In the case of manufactured goods (non-stocked only), the user may be prompted to select options from a material list associated with the manufactured item.

A general SKU is initially used for creating the order. This item is used to create unique "renumbered" items that will be used for order tracking (or manufacturing). Tracking (renumbered) items are created upon processing a transaction containing the base item (generic SKU). Transactions supporting this feature include Orders (Point of Sale), Charge Returns (Point of Sale), Order Entry (Purchasing), Receipts (Purchasing), and Manufacturing (Inventory).

Generated "renumbered" items track quantities and pricing even though they are not stocked. Item settings on renumbered goods should not be modified in order to ensure proper operation.

Stage 2: Goods are Ordered from a Vendor (Purchasing)

This stage is where your company obtains goods from some kind of vendor (aka. supplier, manufacturer, wholesaler, co-op, etc.). To order goods, and track the process accurately, a purchase order is used. The purchase order is a document that your company can provide to a vendor which lists goods your company wants to purchase. A "purchase order" document can be created at the same time as the customer order or later on... this is your company's choice and a procedural preference.

When the non-stocked (renumbered) goods have been "marked as ordered" by the purchaser, the on-order quantities for each item ordered are increased.

Once the goods have been associated with a purchase order and that purchase order provided to the vendor(s), the vendor ships the goods to your company. Until the goods are received, any attempt to sell (invoice) the customer order will result in either a task list error or warning (again, this depends upon your company's preferences).

Note: Non-stocked manufactured goods may contain, or be entirely composed of, components (items) that are also non-stocked. These can be associated with a purchase order in the manufacturing transaction.

Stage 3: Ordered Goods Arrive (Receiving)

When the shipment from the vendor arrives, the purchaser checks-in the goods using the Receiving transaction. The purchaser typically uses the purchase order document to process the received items. The item's on-order quantities are reduced and their on-hand quantities are increased at this time. Receiving is also used for updating item costs.

Manufactured goods may involve the "receiving" step if they include non-stock component items; however, an additional stage, "manufacturing," is also required because your company must produce the goods being manufactured. Until manufacturing (production) is complete, the order (work order) won't be available for sale.

Stage 4: Selling the Order (Sale)

Once your company has the ordered goods in your possession, the customer is contacted and the order may be sold. If some goods were not received (or manufactured), the order can be partially sold and left open for future use. Once a "renumbered" non-stocked item has been sold and is no longer active, it's type is changed to "resale." This is done because an assumption is made that the only further possible use for the unique item would be in the case of a return by the customer.