Understanding the PO Build Quantities Calculation

When you use the Purchase Order Build process, the application calculates the item order quantities for you based on the criteria you specify in the Item Maintenance form and the choices you make during the Build specification process.

In the Item Maintenance form you can specify the Minimum and Maximum order quantities for each item you stock. The Lead time setting defines the number of days it takes to receive the ordered items after you place the order. When the item quantity on hand falls below the Minimum quantity, and you begin the Replenishment Item build process the application uses these Maximum/Quantity On Hand/ and other purchase / committed / return information to quantify the ordered amount:

Maximum - (On-hand + Ordered Due - Committed Due)

Ideally, an item's Maximum should at least be equal to the lowest quantity you can order from the primary vendor for the product. If the Maximum quantity is set below the vendor's minimum, it may still be included on a build as long as the quantity needed is above one or more of the package breaks for the vendor's multiples (if used). The quantity should round up to the selected order multiple in this case.

Another calculation, similar to the eligibility one, is used for determining the quantity to order (aka. quantity needed/required, etc.). This calculation uses the item's BASE measurement for all quantities (the first calculation also does this).

If either no vendor is specified for the current order or there is no matching vendor-item in your inventory, the order quantity may be converted to the item's PO/Receipt Qty unit of measure. If this conversion results in a quantity less than one (1), the application does not include the item will not be included on the build. There can and often are differences in build results depending upon whether a vendor is designated or not. Vendor-item settings are only used if a vendor has been specified for the purchase order at the time the build is processed!

Otherwise, if a vendor is designated, the quantity determined above is now compared to the item's purchase settings for the vendor (if any). Order multiples and units of measure are determined by the vendor; however, break quantities are set at your company's discretion. EDI can update this information automatically if the EDI vendor supplies this information (usually in their catalog update or price update transmissions). Otherwise, vendor multiples can be manually maintained or not used at all. If vendor-specific multiples are not set, the basic calculation shown above determines the order quantity (quantities are converted to either the item's PO/Receipt Qty unit of measure or the vendor-item's Order UM).

How is a Level Selected?

The following logic is applied as long as a vendor has been specified for the purchase order, no branch preferred order multiple has been set for the item (on the Branch, Codes tab in Item Maintenance), and at least one valid multiple exists for the vendor and item. The software selects multiples based upon a best cost method. The multiple that fulfills the required quantity at the lowest cost is selected.

Purchase Order builds determine which level is selected based upon the following rules and conditions:

•For each valid multiple, the software calculates the order quantity (if any) based on the needed quantity, breaks, and the vendor's package quantity if any (and if considered).

•If you don't have order (aka. package) breaks specified for one or more valid levels, each valid multiple with a zero break will be assigned a break quantity automatically. If the multiple is the lowest quantity of the three (3) levels and has a zero break, it will automatically be assigned a break of 1 instead. Higher valid multiples with zero breaks are assigned a break equal to the multiple in BASE terms. Automatically determined breaks are not saved for the item, they are just used for the purposes of finding the best price multiple.

•If your levels are not assigned a re-order cost (a zero cost is the same as no cost), the first non-zero cost associated with the item is used instead (costs are checked in the following order:

(1) Market Cost,

(2) Last Receipt Cost, and

(3) Weighted Average). If all costs are zero, the item will not be ordered.

•The valid level with the lowest cost that would order any quantity of the item greater than zero will be the multiple selected.

•A valid level is any level with an order multiple above zero.

When the vendor's package quantity does not match the item's base unit of measure, this can result in orders that either exceed or don't meet the needed quantity exactly. If you find that builds are ordering either too much or too little, adjust your break quantities accordingly or select a measure that matches the vendors using the drop down.

Example #1:

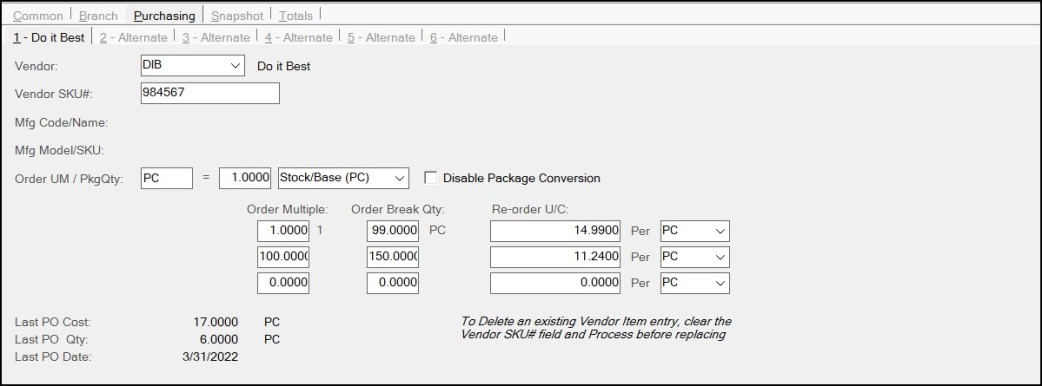

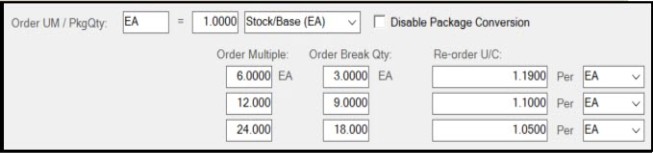

In this example, we have an item whose settings are the following:

If the recommended quantity to order is calculated to be 8, the three levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 1 | 6 @ $1.19 EA | 6 EA |

| Level 2 | 0 | 12 @ $1.10 EA | 0 |

| Level 3 | 0 | 24 @ $1.05 EA | 0 |

The build process chooses the multiple of 6, and 6 EACH would be ordered at the $1.19 cost per EACH.

If the recommended quantity to order is calculated to be 9, the three levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 2 | 6 @ $1.19 EA | 12 EA |

| Level 2 | 1 | 12 @ $1.10 EA | 12 EA |

| Level 3 | 0 | 24 @ $1.05 EA | 0 EA |

The build process cshooses the multiple level 2 (12 EACH), because it has a lower cost, so 12 EACH would be ordered at the $1.10 cost per EACH.

If the recommended quantity to order is calculated to be 18, the three levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 3 | 6 @ $1.19 EA | 18 EA |

| Level 2 | 1 | 12 @ $1.10 EA | 12 EA |

| Level 3 | 1 | 24 @ $1.05 EA | 24 EA |

The build process chooses the multiple level 3 (24 EACH), so 24 EACH would be ordered at the $1.05 cost per EACH.

Example #2:

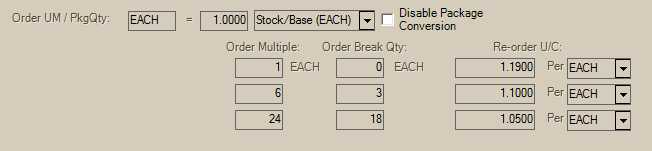

In this example, we have an item whose settings are the following:

If this item's recommended order quantity is 2, the build process would order 2 EACH at the first level (two 1's) and zero at the other levels.

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 2 | 1 @ $1.19 EA | 2 EA |

| Level 2 | 0 | 6 @ $1.10 EA | 0 |

| Level 3 | 0 | 24 @ $1.05 EA | 0 |

However, if the recommended quantity is 14, the three levels would calculate the following quantities:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 14 | 1 @ $1.19 EA | 14 EA |

| Level 2 | 2 | 6 @ $1.10 EA | 12 EA |

| Level 3 | 0 | 24 @ $1.05 EA | 0 EA |

The highest order quantity is provided by the first level (14 - Level 1's), but it's not the best price. The build process would choose the second level and order two 6's (12 EACH units) in this case.

Why? It is assumed that a purchaser would order a bit less at a better price. If this isn't the case, adjust the item's break quantities or you can set a preferred level from the Branch and Codes tab.

Example #3:

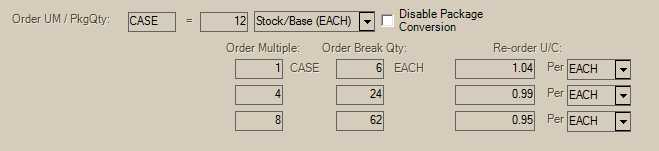

In this example, we have an item whose settings are the following:

Note: One of our vendor's unit (order multiple) is equal to 12 EACH (our item's base quantity), so the Order multiples listed are not in the same unit of measure as our break quantities. In this example, our order break figure appears higher than the multiple, but since one multiple actually represents 12 of each break quantity, this is not actually the case.

If the recommended quantity to order is calculated to be 8, the three levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 1 | 1 CASE@ $1.04 EA | 12 EA |

| Level 2 | 0 | 4 CASE @ $0.99 EA | 0 |

| Level 3 | 0 | 8 CASE @ $0.95 EA | 0 |

The multiple of 1 would be chosen, and 12 EACH (1 CASE) would be ordered at the $1.04 cost per EACH.

If the recommended quantity to order is calculated to be 25, the three (3) levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 2 | 1 CASE @ $1.04 EA | 24 EA |

| Level 2 | 1 | 4 CASE @ $0.99 EA | 48 EA |

| Level 3 | 0 | 8 CASE @ $0.95 EA | 0 EA |

The second level, a multiple of 4, would be chosen because it has a lower cost, so 48 EACH (4 CASE) would be ordered at the $0.99 cost per EACH.

If the recommended quantity to order is calculated to be 71, the three levels would calculate the following:

| Quantity of Level Ordered |

Order Multiple @ Unit Cost |

Net Quantity in BASE Terms |

|

|---|---|---|---|

| Level 1 | 5 | 1 CASE @ $1.04 EA | 60 EA |

| Level 2 | 1 | 4 CASE @ $0.99 EA | 48 EA |

| Level 3 | 1 | 8 CASE @ $0.95 EA | 96 EA |

In this case, the third level multiple of 8 would be chosen, so 96 EACH (8 CASE) would be ordered at the $0.95 cost per EACH.

Understanding the EDI and Vendor Multiples

Some vendors update multiple settings via EDI (Electronic Data Interchange) processing using catalog updates or price updates. If a vendor does this and you process the data, the application can adjust the multipliers and costs automatically. Changes to multiples in the Catalog for the vendor do affect the multiples used for the item.

Both order breaks and preferred multiple settings are solely determined by your company as preferences for ordering, and are never adjusted by EDI. They may require manual adjustment if your vendor chooses to modify other settings. EDI users should review their log files for changes related to multiples to make sure such changes don't affect their ordering preferences in a negative way.