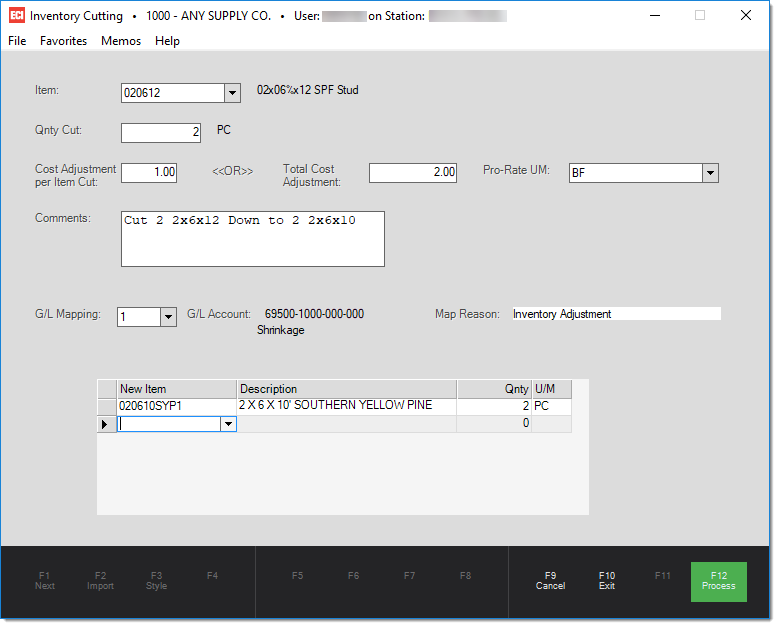

Inventory Cutting Utility

The Inventory Cutting Utility gives you a way to take an item from inventory and "cut" it to another length. This reduces the on-hand inventory for the cut item and increases the on-hand inventory for the resulting items. The cost of the "new" or output items is determined by the cost value of the cut item plus any adjustment you apply. The application pro-rates the cost value based on the unit of measure you choose.

For example, if you select board footage (BF), the total cost value of the cut item (plus or minus any adjustments you add) is pro-rated based on each output item's percentage of the overall resulting board footage (BF). The application does not consider normal cost pricing of the output items.

Reasons for performing a cut include removing damaged sections from lumber so that they can be sold as a different dimension or to replenish stock when there's a shortage. It is the user's responsibility to enter all quantities correctly. This utility program does not verify the quantities entered for validity.

For example, a user can potentially cut one 248 (2" x 4" x 8') pine board into 1,000 pieces of 2410 (2" x 4" x 10'). Double-check all quantities before processing!

Only certain item types are allowed for selection. These include standard, lumber (aka. timber), sheet goods, hardwoods, resale, manufactured, and food. All other types are intentionally excluded. Use good judgment and discretion when cutting items. Items which have no on-hand or don't maintain on-hand should probably not be cut.

Weighted average cost is used for determining the cost value of the "cut" item. An adjustment record is generated for each output item and the items' weighted average costs are re-calculated when appropriate.

Users can optionally include a cost adjustment amount. Adjustments either increase or decrease the resulting cost of the output items:

-

Positive adjustment amounts increase the output items' costs.

-

Negative adjustment amounts decrease the output item costs.

You can enter adjustment amounts as either a "per item cut" amount or a "total adjustment amount." When the quantity of the cut item is 1, these figures are both the same.

Procedures

Begin by entering or selecting the item that will be cut. Enter the quantity of the "cut" item using the unit of measure (U/M) displayed to the right of the quantity input box. In the grid, enter the item or items that will be created when the item is cut. If a cost adjustment should be applied, enter either (1) the amount "per item" (per cut item, not the output items) or (2) the "total adjustment." If the quantity of the item being cut is ONE (1), these figures will match each other. The "Pro-rate U/M" (unit of measure) determines how the cut item's cost and any adjustment amount is used when determining the cost of output items.

-

If a pro-rate U/M (unit of measure) of board feet (BF) is used, output items' costs calculate based upon that item's percentage of the total resulting board footage. For example, a board with the dimensions of 2" x 4" x 16' has a total board footage of 10.6667 (per each). If this board is cut into one 2" x 4" x 8' (5.3333 BF per PC), one 2" x 4" x 6' (4.000 BF per PC), and there's 2' remaining of waste lumber, the total output would be 9.3333 board feet (not including the waste).

-

If a cost value of $4.50 plus adjustment total of $1.00 is applied (totaling $5.50) using BF (board feet) as the pro-rate U/M selection, the 248 item would receive 57% ($3.135) of the adjustment and the 246 item would receive 43% ($2.365). Because of rounding, the adjustment amount may be changed slightly during processing to force an even distribution of costs avoiding partial cents.

-

If the adjustment's Pro-rate U/M was set to PC (or EACH) instead, each cut item would receive approximately 1/2 of the cost plus (or minus) adjustment total. Why? This happens because the ending items each represent 50% of the total PC count of output items (2 pieces total, one of each item). Except in cases where lumber items are being cut into pieces of equal dimensions, it makes the most sense to pro-rate adjustments by either board footage (volume) or lineal footage (length).

Processing

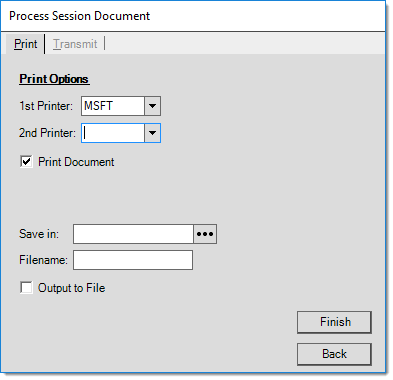

When all information is complete, press or select the Process (F12) button. A process form will open. This form can be used to print, create a file, or transmit the Inventory Cutting session document. Transmit options such as E-mail and Faxing require additional set-up and third party integration to function. Cutting documents are retained for future review and can be accessed using the Documents tool (document type description is IN Inventory Adjustments).